Automatic Servo Softgel Capsule Making Line FS-130

Application

Feature

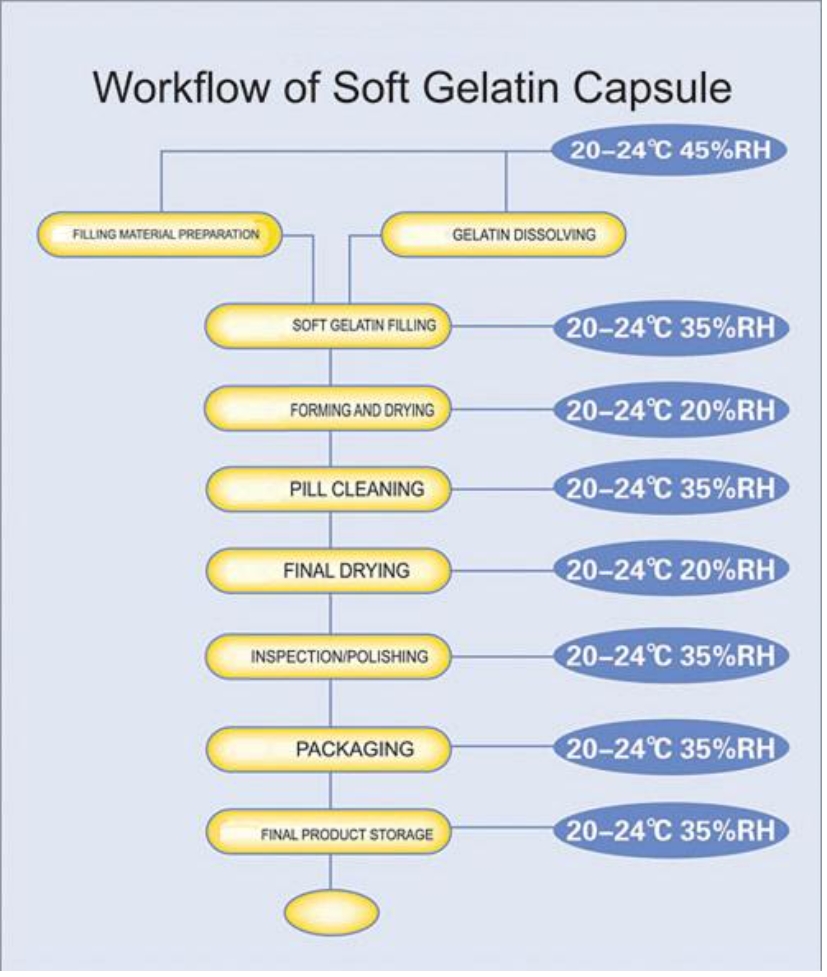

Workflow Of Soft Gelatin Capsule

Technical Parameters

|

Main machine |

Model FSC-200 |

|

Roller Die Dimension: |

Φ103x200 mm |

|

Roller Die Pressure: |

0.1-0.5MPa |

|

Roller Die Speed: |

0-6rpm Stepless Speed Adjust |

|

Material Feeding Quantity: |

12 X (0-2)mL |

|

Filling Quantity Precision: |

<500mg, ±1% ; >500mg, ±0.5% |

|

Power: |

AC380V 50Hz 7kW |

|

External Size: |

1680×770×1800mm |

|

Weight: |

1250kg |

Conveyor

|

Stainless Steel Conveyor |

|

|

Power: |

220V,0.37KW |

|

Wind pressure: |

900pa |

|

Wind quantity: |

2000 m3/h |

Electrical Control Panel

|

Micro-lubricating System |

|

Oil box,adjustable flow control valve |

|

Gelatin Film Spreading |

|

Speater Box(0.01mm) |

|

PID temperature control |

|

Temperature sensor(0.1℃) |

|

Cooling water machine |

|

|

Power: |

AC220V 50Hz 1.5kW; |

|

Cooling Liquid Quantity: |

55L |

|

Cold {Producing} Medium: |

R22 |

|

Cooling Liquid Type: |

-40℃ Anti-Icing Fluid |

|

Connecting Part : |

G1/2“ |

|

External Size: |

650×360×850mm |

|

Weight: |

70kg |

Setting And Drying Cage

|

Size of rotating cage: |

Φ610×960mm |

|

Rotation rate of rotating cage: |

18rpm |

|

Power: |

AC380V 50Hz 1.2kw |

|

Wound rate of fan: |

3000m3/h |

|

Weight: |

200kg |

|

External size: |

1040×760×1180mm |

|

Size of rotating cage: |

Φ610×960mm |

|

Rotation rate of rotating cage: |

18rpm |

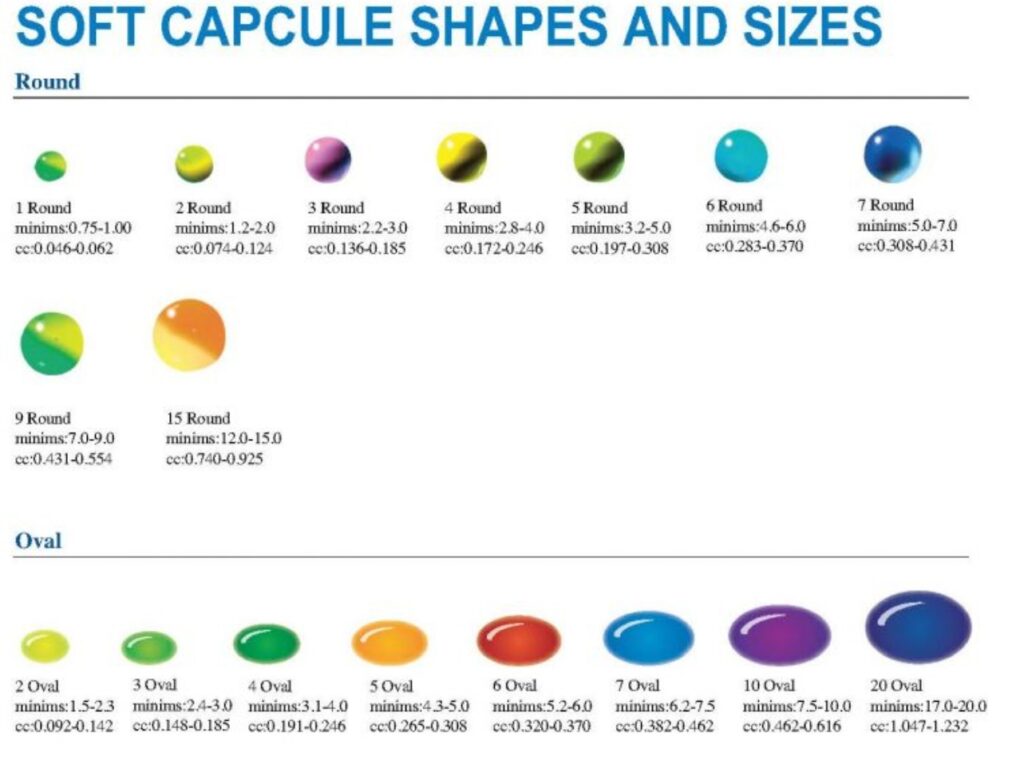

Softgel Capsule Sample