High Efficient Coating Machine FBG-150

Introduction:

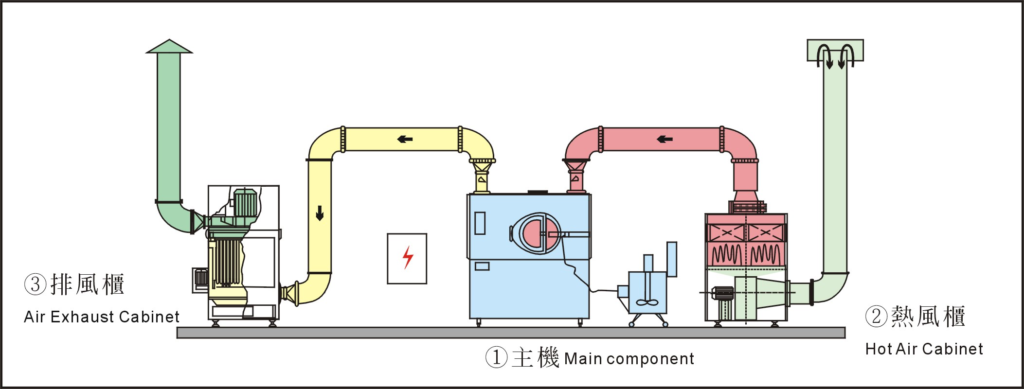

In the film coating machine, the pills and tablets go through a complex and continuous path within a clean and enclosed drum, smoothly rotating and frequently changing positions. The coating materials from the stirring tank are sprayed onto the tablets using a spray gun, powered by the peristaltic pump. Meanwhile, under the action of air exhaust and negative pressure, the clean hot air from the hot air cabinet is expelled through the fan at the sieve pore, passing through the tablets. This process helps dry the coating materials on the tablet surfaces,resulting in a strong, fine, and smooth film.

Machine material and surface disposal

The coating drum is made of stainless steel to ensure suitable for contact with medicines. Both the inside and outside of the drum and the paddles, undergo a bright surface polishing, maximizing the preservation of tablet integrity and beauty.Other parts also made of stainless steel, it is in accordance with GMP, the coating process is carried out in a completely closed state. The stainless steel machine shell seal and decorate for easier to clean. The machine’s outer surface is treated with matte and sandblasting, resulting it a clear texture and an attractive appearance.

Main machine for coating machine

The machine adopt a new microcomputer PLC module, all parameter settings such as hot air temperature, air volume control, and drum speed adjustment etc which are operated through the touch screen. The touch screen is fully sealed, ensuring that the main machine remains unaffected during cleaning. It is reliable and stable in performance, with programmable capabilities. The coating drum is driven in a clockwise direction by an explosion-proof motor via a cycloidal pinwheel.b) The exhaust outlet is equipped with an adjustable device, allowing even a small amount of tablets to undergo the coating in the coating pan. It also has an anti-backflow function, preventing the return of waste gas from the exhaust cabinet.

3.Each seal area does not divulging, and no dust to fly, high-temperature resistant sealing rings are used.

4. Due to the negative pressure exceeding 10 Pa during the coating process in the coating pan, heat dissipation not easy. So the chamber is designed with a hollow box-style structure to ensure that the outer surface temperature does not exceed 15°C during operation.Equipped with a negative pressure gauge to ensure keep a negative pressure state inside. This also prevents powder from blowing out when open the door, avoiding the inhalation of dust by operating personnel.

5.Under the action of the baffle plate, the tablets flip smoothly, exchange frequently, and eliminate the phenomenon of tablets colliding from a height, thereby resolving issues of fragmentation and chipping. The narrow baffle surface eliminates material adhesion, saving material and enhancing pharmaceutical quality.

Hot air circulate system

The air is drawn in by a centrifugal fan and can be heated and dried using either a steam heat exchanger or an electric heat exchanger. Additionally, it is filtered by a three-effect filter, achieving a purification level of 100,000, and then blown into the main machine’s drum. The machine is equipped with anti-vibration and silencer device. The temperature and air flow can be adjusted via the touchscreen.

A differential pressure gauge can be installed on the high-efficiency filter to detect whether the filter is clogged.(option)

The exhaust cabinet is used to extract air from the machine drum and keep a negative pressure within the working area. It is equipped with an automatic mechanical vibrating fabric dust collector that achieves a 99% dust removal efficiency and effectively separates residual dust to prevent it from spreading. The system is easy to clean, and the exhaust emissions comply with environmental regulations.

The air inlet and outlet with air volume regulating valve, it’s easy adjust air volume on touch screen.

Spray device

-a) Spray gun adjustment: It’s can adjust the distance and spraying angle between the spray gun and the tablet, as well as the air pressure and flow rate, to meet various requirements as needed. Additionally, you can set the spray rate and mode to achieve more precise and flexible coating operations.

b)Thermostatic stirring tank(see fig.4) with electric heating, temperature can controlled, and an pneumatic agitator powered by compressed air, rotate speed is stabilization, ensuring even mixing of the medium. The temperature range is from room temperature to 80℃, easy to operation, safe and credibility. All made of stainless steel. The surface which inside and outside are bright polishing, it is in accordance with GMP.

c) Syrup pump (frequency speed adjustment) with impeller drive structure, enhanced the pump’s power, It effectively handles the thick liquid coating process in sugarcoating, resolving the issue of peristaltic pumps inefficiently transporting viscous liquids. It is suitable for coating -a syrup.

![]() The film coating adopt Peristaltic pump(Lange Brand).

The film coating adopt Peristaltic pump(Lange Brand).

Technical Parameter

|

Eredu |

FBG-150 |

|||

|

Max. loading volume |

150L / batch |

|||

|

Capacity(as per specific gravity:0.8) |

120kg/batch |

|||

|

Coating drum speed |

1-16 r.p.m |

|||

|

Hornidura tentsioa |

3P 380V 50Hz |

|||

|

Main machine motor power |

2.2 kw |

|||

|

Exhaust cabinet motor power |

5.5 kw |

|||

|

Exhaust blower air flow |

7419 m3/h |

|||

|

Hot air cabinet motor power |

1.5 kw |

|||

|

Air heater air flow |

2356 m3/h |

|||

|

Air heater temp.-adj. irismen |

~ 80 ℃ |

|||

|

Hot air cleanness |

100,000 level |

|||

|

Pump motor power |

0.55kw |

|||

|

External dimensions of host machine(mm) |

1570×1260×2030 |

|||

|

Host machine weight |

1020kg |

|||

|

External dimensions of hot air cabinet(mm) |

1000×900×2300 |

|||

|

Hot air cabinet weight |

420kg |

|||

|

External dimensions of exhaust cabinet(mm) |

950×950×2200 |

|||

|

Exhaust cabinet weight |

530kg |

|||

|

External condition |

Clean air |

Presio |

³0.4Mpa |

|

|

|

|

Air consumption |

1m 3/min. |

|

|

|

Steam heating |

steam |

Presio |

³0.4Mpa |

|

|

|

|

Air consump. |

100kg/h |

|

|

|

Power source |

3 phase and 5 lines 10 kw |

|

|

|

Electric heating |

Power source |

3 phase and 5 lines 38 kw |

|