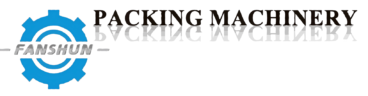

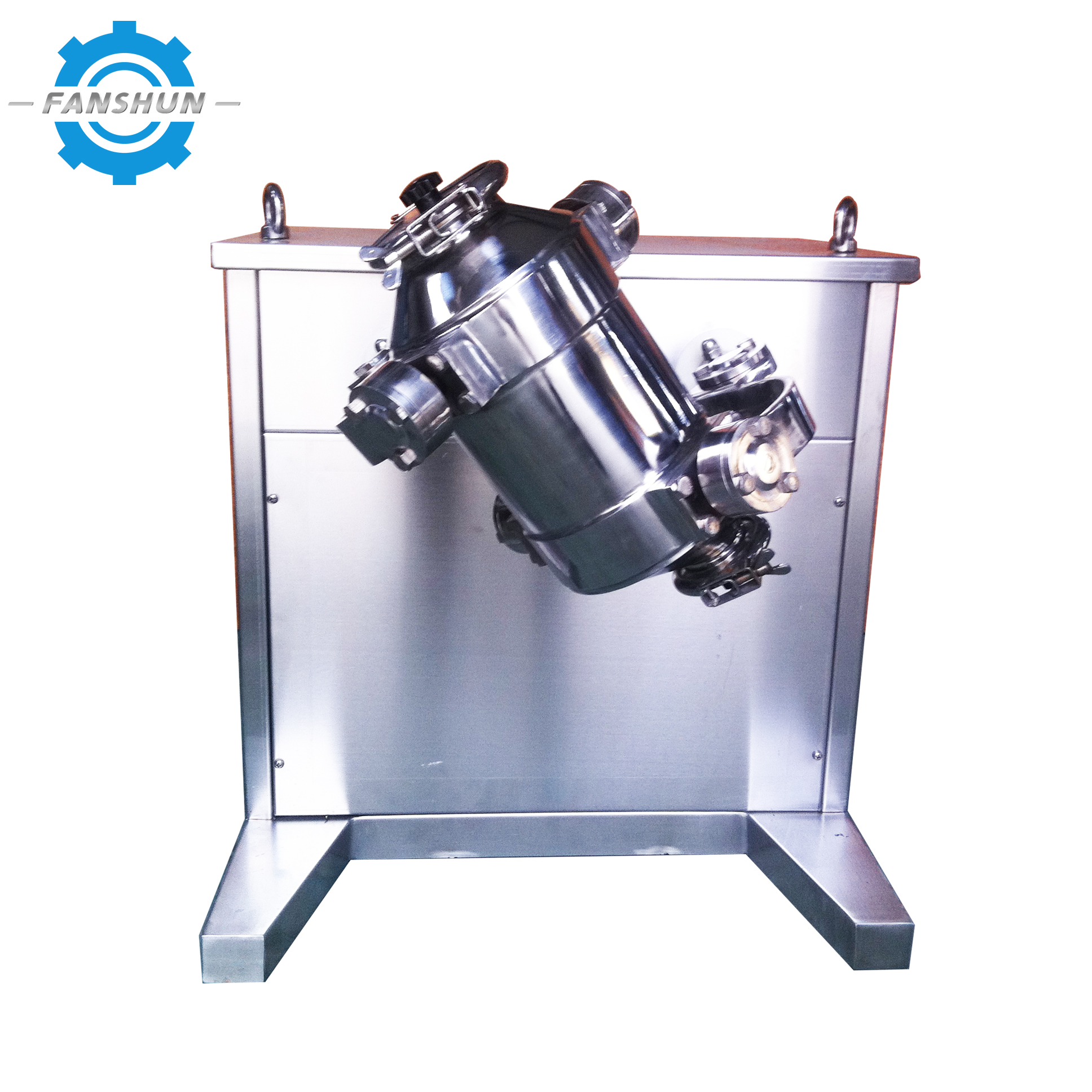

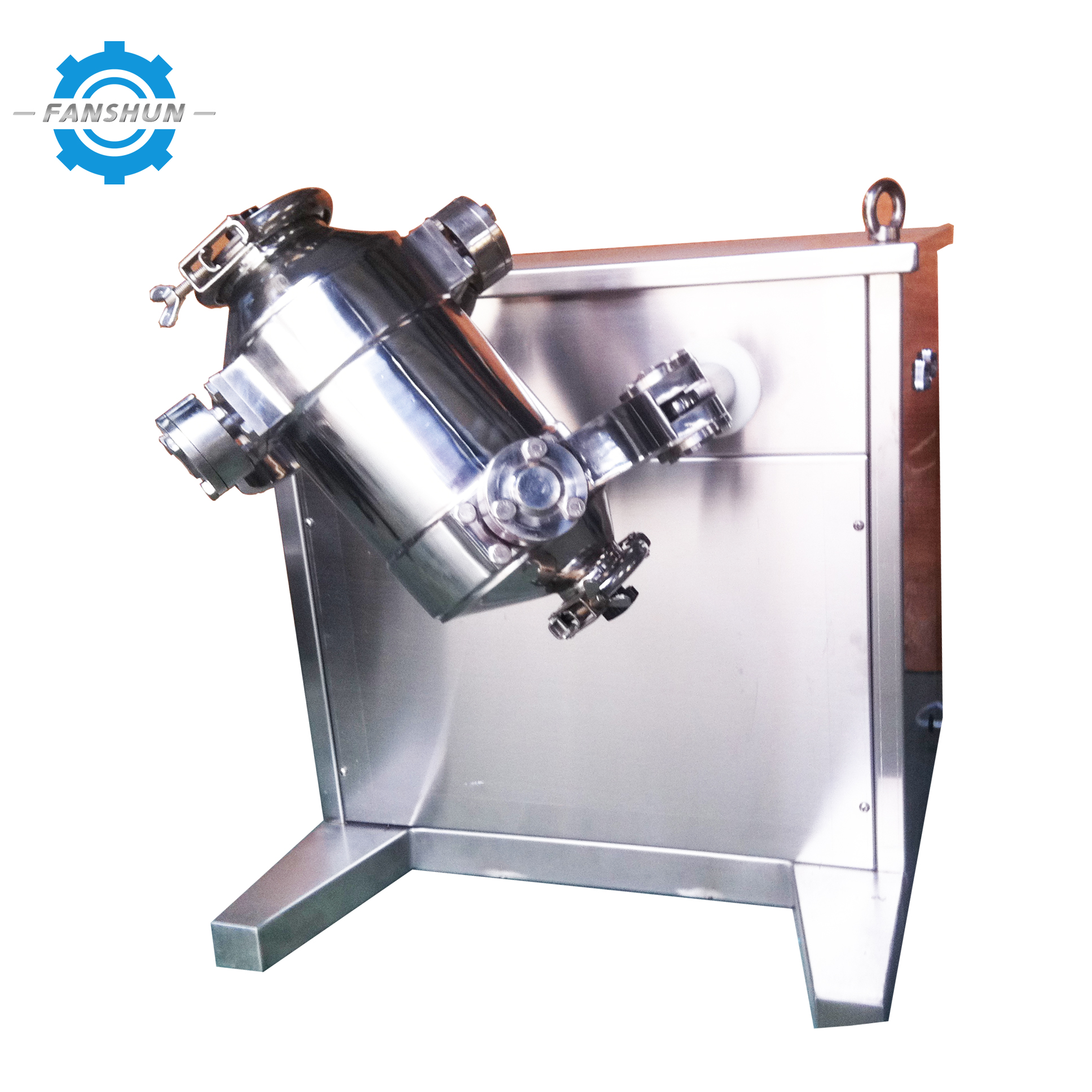

Three Dimensional Mixer SDM-50

Working principle:

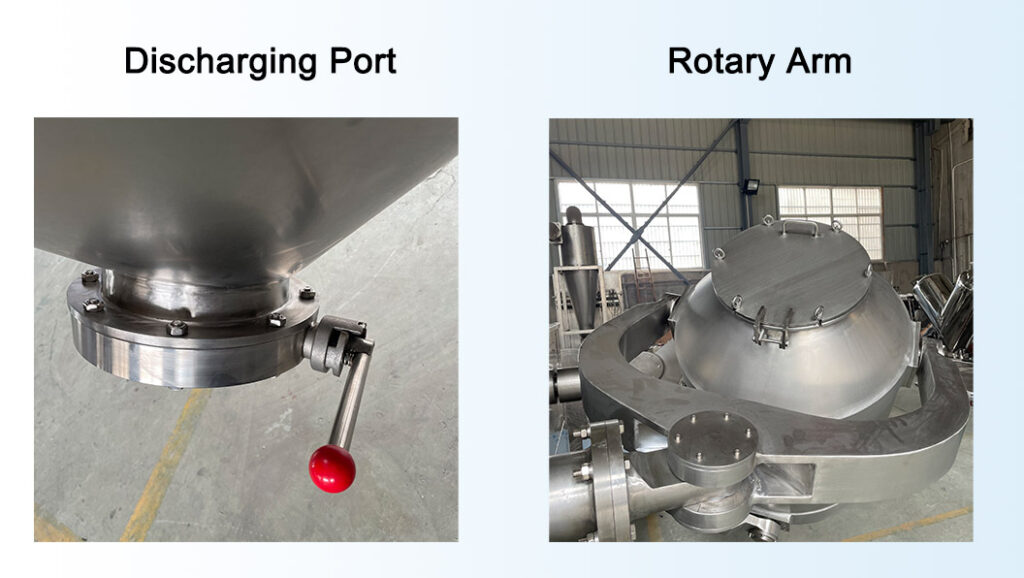

Driven by the active shaft, the composite cylinder containing the mixture material performs compound movements such as translation, rotation and tumbling, which promotes the three-directional compound movement of the ring, radial and axial along the inner surface of the cylinder. In order to achieve the mutual flow, diffusion, accumulation, and doping of various materials, to achieve the purpose of uniform mixing.

Application

Widely used in high uniformity mixing of powdered and granular materials in pharmaceutical, chemical, food, light industry, electronics, machinery, mining and metallurgy, national defense industry, and various scientific research units.

Main features

- Due to the multi-directional movement of the mixing barrel, the material basically has no centrifugal force, no specific gravity segregation and layering and accumulation. Each component can have a disparate weight ratio, and the mixing rate can reach more than 99.9%, which is one of the most ideal products in the mixer type.

- The filling rate of the cylinder is large, up to 75-80% (common mixer is only 40%), with high efficiency and short mixing time.

- The arc is used excessively everywhere in the cylinder, and the inner and outer surfaces are precision polished, so the appearance is beautiful.

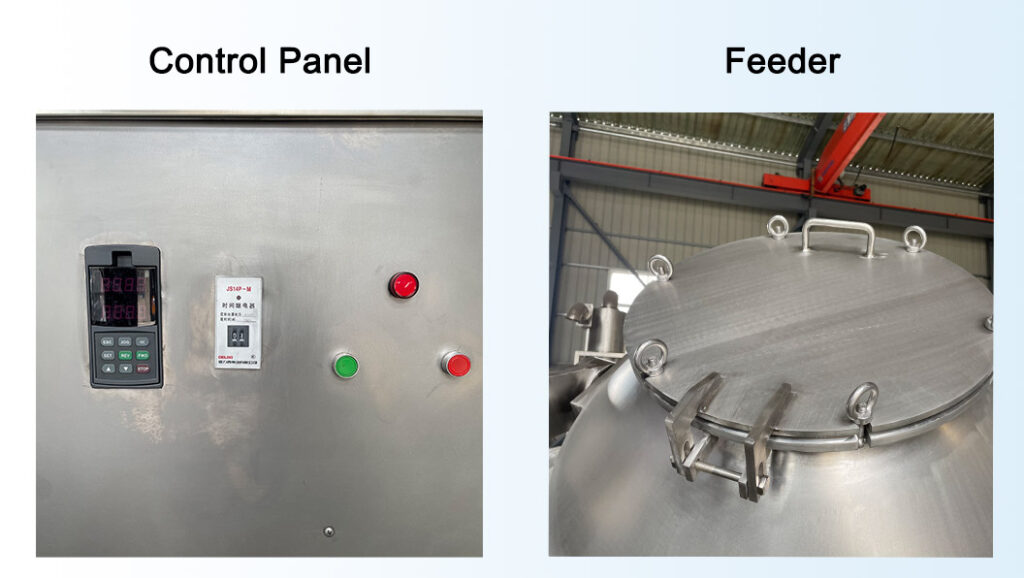

- Stable and reliable operation, low vibration, easy operation and maintenance.

Technical parameter:

Model | SDM-50 |

Volume of mixing vat(L) | 50 |

Max.Charging Volume(L) | 40 |

Rotation Speed of spindle(R/min) | 0-12 |

Power(KW) | 1.5 |

Weight(KG) | 300KG |