Semi Automatic Capsule Filling Machine FTJ-Z PRO

Introduction:

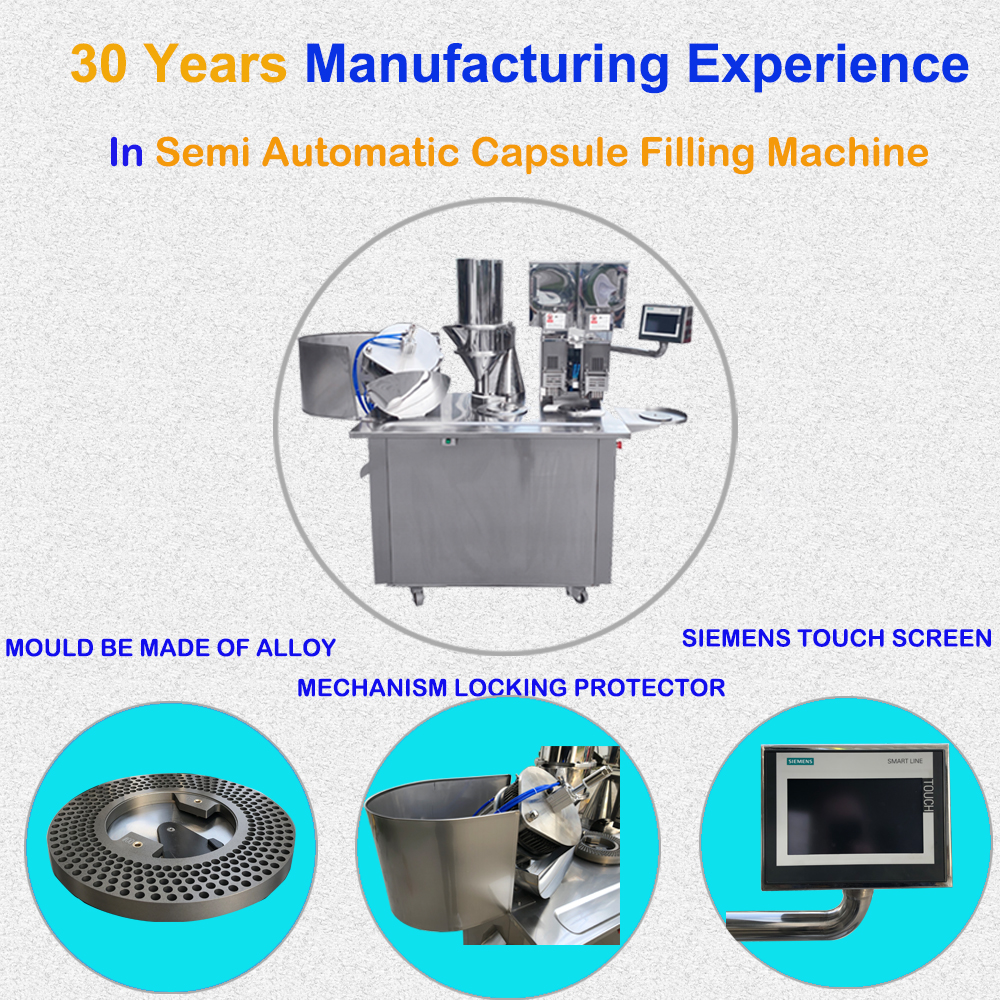

FTJ-Z Pro semi-automatic capsule filling machine is the upgraded FTJ-Z model, designed with integration of mechanics, electrics and pneumatics. The whole machine is made of stainless steel 304 and suitable for filling capsule with powder and granular drugs.

1. With accumulated production experience in manufacturing several thousand sets of FTJ-Z Capsule Filling machine, FANSHUN PACKING MACHINERY developed the latest FTJ-Z Pro which can work more efficiently and smoothly. Numerous innovative operational and safety features that streamline the production process and the production speed rises up to 50,000 capsules per hour. The capsule filler can handle all capsule sizes from 000# to 5#. A special design allows the mould charging for different size capsules within 15 minutes easily, simply, and precisely. It can fill material in powder, pellet, or granule forms. Each machine is tested by FANSHUN PACKING MACHINERY laboratory, with failure-free in 10,000 hours of operation.

2. The traditional key switch is replaced with the touch screen, which makes the operation more easy and convenient.

3. The capsule feeding mechanism is made of 100% SS304 instead of the copper one of FTJ-C, which makes the whole production process comply with GMP standard.

4. The empty capsule sowing speed can be adjusted, which reinforces the sowing accuracy according to the real demand. The evident advantage of this machine is that with the 2 capsule sowing nozzle, the productivity is doubled in this stage.

5. The hole on the plate for the capsule is a little inclined instead of 100% vertical, which can reduce to the maximum the sowing error.

6. The whole capsule mould, coated by the black hard alloy that you can see in the picture under the main machine, makes the machine’s life doubled.

In a word, with novel structure, elegant appearance and convenient operation, it is the most ideal capsule filling equipment in pharmaceutical industry for small production and laboratory use.

Main technical parameters

|

Productivity |

30000—50000pcs/h |

|

Capsule size |

From 000# to 4# |

|

Filling material |

Powder/small granules |

|

Compressor (included) |

0.05m3/min 0.7MPa |

|

Vacuum pump (included) |

Suction performance 40m3/h |

|

Power supply |

3 phases 2.2KW |

|

Machine measurement |

1.65×0.8×1.75(m) |

|

Package measurement |

1.8×0.8×1.75(m) |

|

Machine weight |

500Kg |

Configuration List

|

Product Name |

Type |

Brand |

Qty. |

Remarks |

|

Frequency Converter |

S310-201HIBCD |

Teco |

3 |

Taiwan |

|

Intermediate Relay |

MY4N-SS |

OMRON |

9 |

Japan |

|

AC relay |

LCIN1210M5N |

Schneider |

1 |

France |

|

Breaker |

IC65NC25 |

Schneider |

1 |

France |

|

Breaker |

IC65NC16 |

Schneider |

1 |

France |

|

Emergency stop switch |

ZB2BS54C |

Schneider |

1 |

France |

|

touch screen |

6AV6648-0CC11-3AX0 |

SIEMENS |

1 |

Germany |

|

PLC programmable controller |

6ES7-288-1ST30-0aa0 |

SIEMENS |

1 |

Germany |

|

Photoelectric switch |

GL-8F |

SUNX |

1 |

Japan |

|

Proximity switch |

PR12-4DN |

Autonics |

|

Korea |

|

Switching power supply |

NFS-24-50 |

NVW |

1 |

Taiwan |